Industrial Packaging: Engineering Durability for Maximum Logistics Efficiency

Industrial packaging demands far exceed consumer goods requirements, where heavy machinery, chemical products, and bulk materials need protection through complex supply chains. The stakes are higher, the loads heavier, and the consequences of packaging failure can result in catastrophic losses exceeding hundreds of thousands of dollars per incident.

Modern industrial operations require packaging solutions that balance extreme durability with logistics efficiency, creating systems that protect valuable cargo while optimizing transportation costs and warehouse operations. This strategic approach transforms packaging from a necessary expense into a competitive advantage.

Understanding Industrial Load Requirements

Industrial packaging must withstand forces that would destroy conventional packaging systems. Dynamic loads during transportation, stacking pressures in warehouses, and environmental extremes create demanding performance requirements. Engineers calculate load distribution, vibration resistance, and compression strength to ensure packaging integrity throughout the entire logistics chain.

Custom-engineered industrial crates distribute heavy loads safely while providing integrated handling features for warehouse efficiency.

Custom-engineered industrial crates distribute heavy loads safely while providing integrated handling features for warehouse efficiency.

Heavy industrial components often require custom-engineered packaging solutions that distribute weight evenly while providing access points for handling equipment. These systems must accommodate forklifts, cranes, and automated handling systems without compromising structural integrity or worker safety.

Material Selection for Extreme Conditions

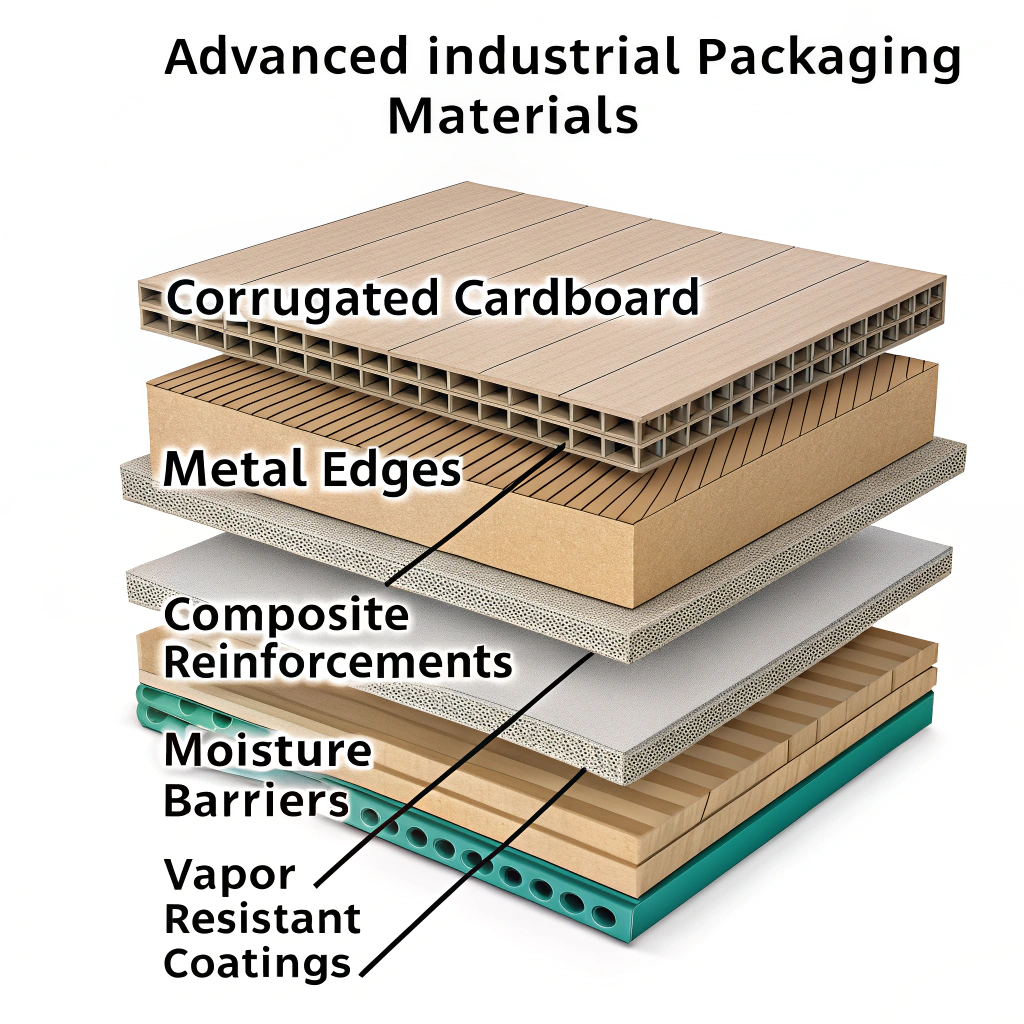

Industrial packaging materials must perform reliably under conditions that include temperature extremes, moisture exposure, and chemical resistance. High-density corrugated cardboard, reinforced with metal edges, provides exceptional strength-to-weight ratios for medium-duty applications. Heavy-duty applications demand engineered wood crates, steel containers, or hybrid solutions combining multiple materials.

Advanced composite materials are revolutionizing industrial packaging by offering superior protection with reduced weight. Carbon fiber reinforced plastics and high-performance polymers create packaging that withstands extreme impacts while reducing shipping costs through weight optimization.

Advanced composite materials and specialized coatings provide superior protection under extreme industrial conditions while optimizing weight.

Moisture barriers and vapor-resistant coatings protect sensitive equipment during long-term storage or international shipping. These specialized treatments prevent corrosion, contamination, and degradation that could render expensive industrial equipment unusable.

Modular Systems and Standardization

Modular packaging architectures enable efficient logistics operations by standardizing dimensions across product lines. Interchangeable components reduce inventory complexity while ensuring optimal space utilization in containers and warehouses. These systems adapt to various product sizes using common base platforms, reducing packaging costs and simplifying logistics planning.

Standardized industrial packaging dimensions align with international shipping containers, maximizing cargo capacity and reducing transportation costs. Smart companies design packaging systems that nest efficiently when empty, minimizing return logistics expenses.

Integrated Handling and Protection Features

Modern industrial packaging incorporates handling features directly into the protection system. Integrated lifting points, forklift channels, and crane attachment systems eliminate the need for additional handling equipment while ensuring safe material movement. These features reduce loading times and minimize handling damage risks.

Smart industrial packaging incorporates monitoring technology for real-time condition tracking and automated logistics optimization.

Anti-static properties, shock absorption systems, and vibration damping protect sensitive electronic components and precision instruments. Multi-layer protection systems combine rigid outer shells with engineered cushioning materials that absorb impacts while maintaining dimensional stability.

Technology-Enhanced Monitoring and Tracking

Smart industrial packaging incorporates sensors that monitor environmental conditions, impact events, and handling parameters throughout the logistics chain. These systems provide real-time alerts for temperature excursions, excessive vibration, or unauthorized access, enabling proactive intervention before damage occurs.

RFID integration and GPS tracking provide complete visibility into packaging location and condition, optimizing inventory management and reducing loss rates. Automated data collection eliminates manual inspection requirements while providing detailed logistics performance analytics.

Cost Optimization Through Lifecycle Analysis

Effective industrial packaging requires comprehensive lifecycle cost analysis that considers initial packaging costs, transportation efficiency, damage prevention, and end-of-life disposal. Premium packaging materials often deliver superior total cost performance by preventing expensive damage claims and reducing replacement costs.

Reusable industrial packaging systems provide exceptional long-term value by amortizing initial investments across multiple shipments. Steel containers, engineered wood crates, and modular plastic systems can serve hundreds of logistics cycles while maintaining protection performance standards.

Industrial packaging excellence demands strategic thinking that balances immediate protection needs with long-term logistics efficiency, creating sustainable competitive advantages through superior cargo protection and operational optimization.

At Imperial Paper, we help businesses of all sizes design packaging that protects, performs, and delights. From sturdy shipping boxes to branded unboxing experiences, we’ve got you covered.

📞 Talk to our team or explore our eco-friendly, customizable packaging solutions today.

Need smaller quantities or more personalized packaging options? Visit our partner site BestBoxStore.com—perfect for boutique brands, creative campaigns, and custom low-volume orders.