Supply Chain Resilience

Supply chain disruptions have become increasingly common, forcing businesses to rethink their packaging strategies for uncertain times. Building resilient packaging supply chains requires proactive planning, diversification, and innovative approaches that can withstand various challenges while maintaining cost-effectiveness and quality standards.

Understanding Supply Chain Vulnerabilities

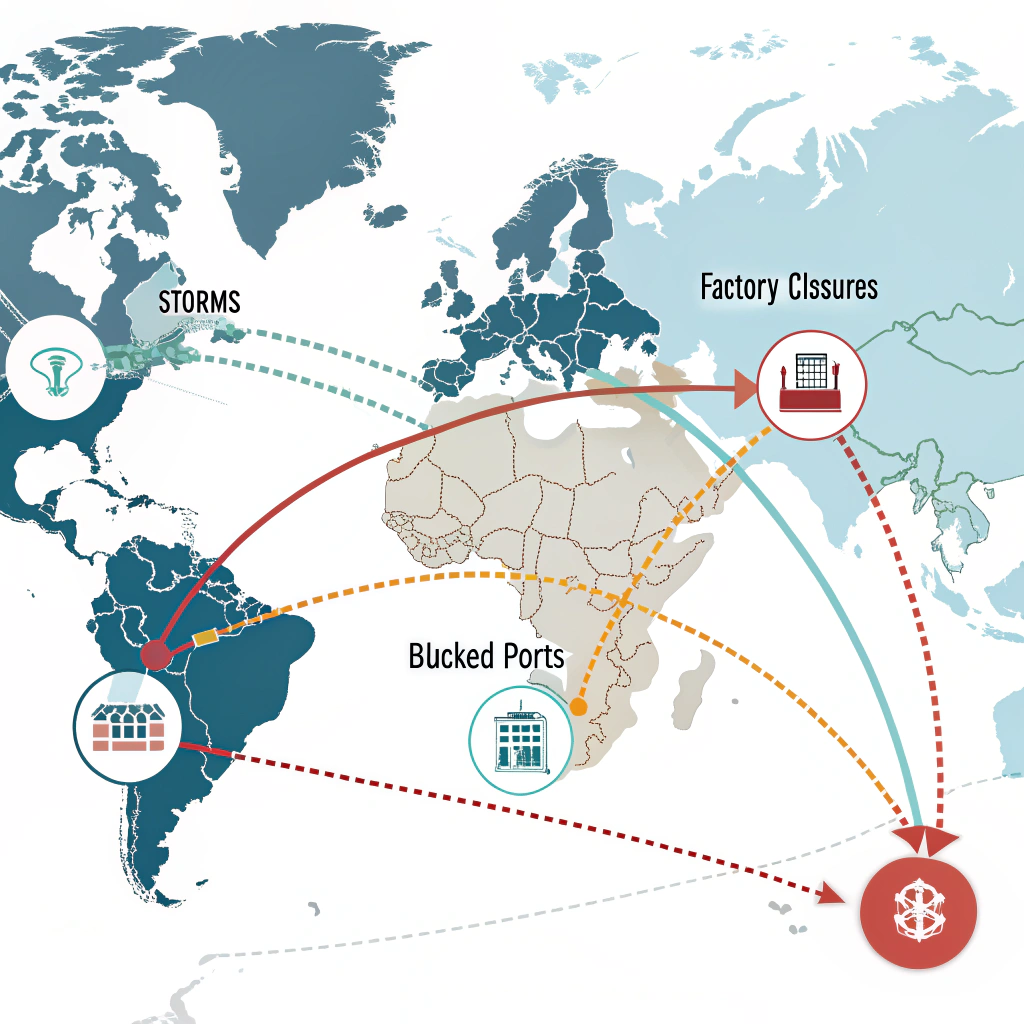

Modern packaging supply chains face numerous potential disruptions including natural disasters, geopolitical tensions, pandemic restrictions, raw material shortages, and transportation delays. These challenges can quickly escalate from minor inconveniences to business-threatening crises without proper preparation.

Recent global events have highlighted the fragility of just-in-time inventory systems and single-source supplier relationships. Companies that previously relied on lean inventory management discovered the importance of building buffer stocks and backup systems to maintain operations during disruptions.

Understanding these vulnerabilities is the first step toward building resilient packaging supply chains that can adapt to changing conditions while maintaining product quality and customer satisfaction.

Supply chain vulnerabilities require diversified strategies to maintain packaging material flow during disruptions

Diversification Strategies for Packaging Materials

Effective supply chain resilience begins with diversifying packaging material sources and suppliers. Key strategies include:

Multiple Supplier Networks: Establish relationships with suppliers in different geographic regions to reduce risk from localized disruptions. This approach ensures alternative sources when primary suppliers face challenges.

Material Substitution Plans: Develop approved alternative materials that can replace primary packaging materials during shortages. This requires advance testing and qualification to ensure performance standards are maintained.

Regional Sourcing: Balance global cost advantages with regional sourcing benefits. Local suppliers may offer higher unit costs but provide greater reliability and shorter lead times during disruptions.

Supplier Financial Health Monitoring: Regularly assess supplier financial stability and operational capacity to identify potential risks before they impact your supply chain.

Inventory Management for Uncertainty

Traditional just-in-time inventory systems must be balanced with strategic stockpiling for critical packaging materials:

Safety Stock Optimization: Calculate appropriate safety stock levels based on demand variability, lead time uncertainty, and criticality of materials.

ABC Analysis: Classify packaging materials by importance and adjust inventory strategies accordingly. Critical materials may require higher safety stocks while less critical items can maintain lean inventory.

Demand Forecasting: Invest in advanced forecasting tools that consider multiple variables and scenarios to improve inventory planning accuracy.

Strategic inventory management balances cost efficiency with supply chain resilience through organized safety stock systems

Technology Solutions for Supply Chain Visibility

Technology plays a crucial role in building resilient packaging supply chains:

Real-Time Tracking: Implement systems that provide real-time visibility into supplier performance, inventory levels, and transportation status.

Predictive Analytics: Use data analytics to identify potential disruptions before they occur and automatically trigger contingency plans.

Blockchain Integration: Employ blockchain technology to create transparent, immutable records of supply chain transactions and material provenance.

Automated Alerts: Set up systems that automatically notify relevant personnel when predetermined thresholds are reached or disruptions occur.

Building Flexible Manufacturing Capabilities

Manufacturing flexibility enhances supply chain resilience by enabling rapid adaptation to changing conditions:

Multi-Format Production: Invest in equipment that can produce multiple packaging formats to maximize flexibility during material shortages.

Modular Design Systems: Develop packaging designs that can accommodate different materials while maintaining functionality and brand consistency.

Cross-Training Programs: Train staff on multiple packaging processes to ensure operational continuity during personnel disruptions.

Flexible manufacturing capabilities enable rapid adaptation to supply chain disruptions and material availability changes

Partnership and Collaboration Strategies

Strong partnerships enhance supply chain resilience through shared resources and information:

Supplier Development Programs: Work closely with key suppliers to improve their resilience and capabilities, creating mutual benefits.

Industry Collaboration: Participate in industry initiatives that share best practices and coordinate responses to supply chain challenges.

Customer Communication: Maintain open communication with customers about potential impacts and alternative solutions during disruptions.

Risk Assessment and Scenario Planning

Comprehensive risk assessment enables proactive planning for various disruption scenarios:

Scenario Modeling: Develop detailed scenarios for different types of disruptions and create specific response plans for each situation.

Regular Risk Reviews: Conduct periodic assessments of supply chain risks and update contingency plans accordingly.

Stress Testing: Regularly test supply chain resilience through simulated disruptions and exercises.

Financial Resilience Considerations

Supply chain resilience requires financial planning to manage increased costs during disruptions:

Insurance Coverage: Evaluate insurance options that cover supply chain disruptions and business interruption costs.

Financial Reserves: Maintain adequate financial reserves to manage temporary cost increases during supply chain disruptions.

Cost-Benefit Analysis: Regularly evaluate the cost-effectiveness of resilience investments against potential disruption costs.

Conclusion

Building resilient packaging supply chains requires a comprehensive approach that balances efficiency with preparedness. By diversifying suppliers, optimizing inventory management, leveraging technology, and building flexible capabilities, companies can navigate uncertain times while maintaining operational continuity. The investment in supply chain resilience pays dividends not only during disruptions but also in improved overall operational performance and customer satisfaction.

At Imperial Paper, we help businesses of all sizes design packaging that protects, performs, and delights. From sturdy shipping boxes to branded unboxing experiences, we’ve got you covered.

📞 Talk to our team or explore our eco-friendly, customizable packaging solutions today.

Need smaller quantities or more personalized packaging options? Visit our partner site BestBoxStore.com—perfect for boutique brands, creative campaigns, and custom low-volume orders.