Faster Delivery With Efficient Packaging

In the competitive world of e-commerce and product distribution, delivery time can make or break a sale. But what many brands overlook is how much packaging affects speed. Choosing the right packaging can significantly accelerate your shipping process, reduce delays, cut costs, and boost customer satisfaction.

In this article, we’ll explore how efficient packaging contributes to faster deliveries—and how you can implement these strategies in your business starting today.

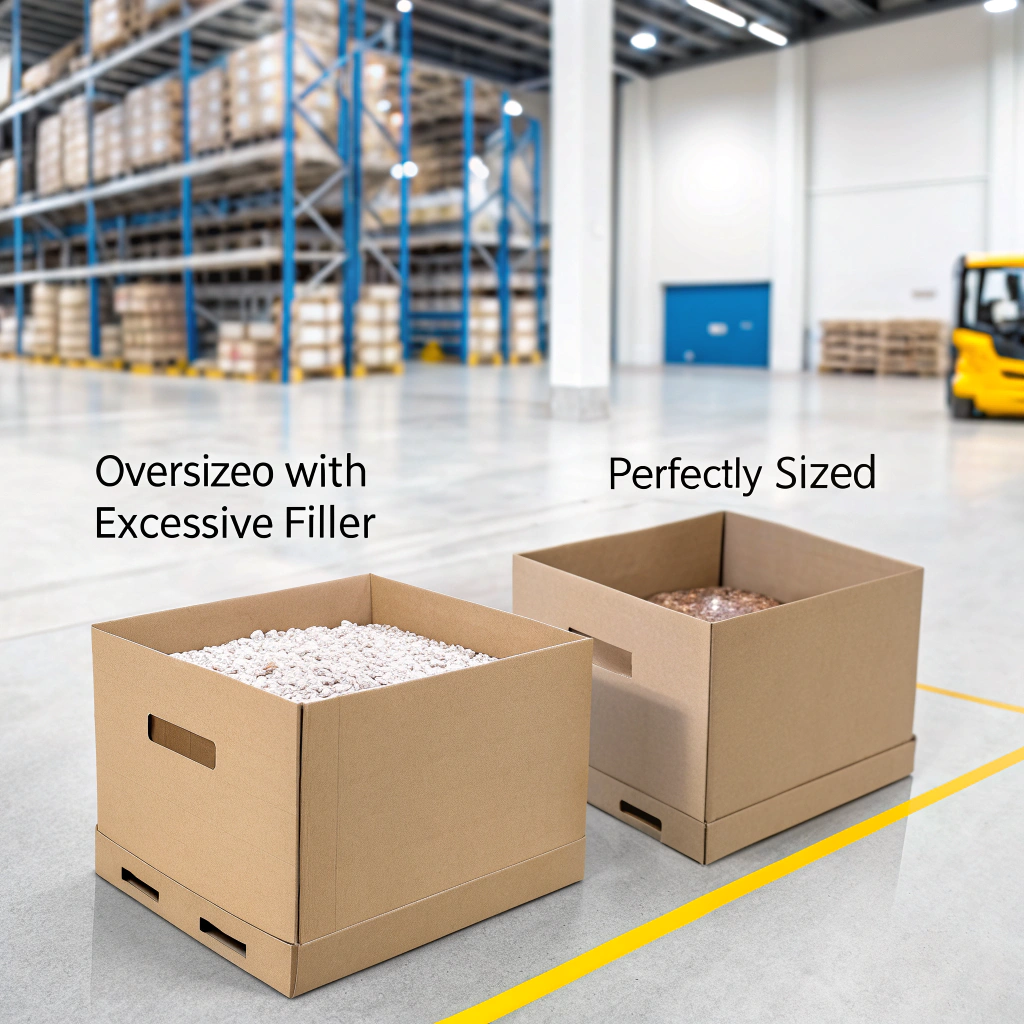

1. Right-Sized Packaging Accelerates Handling

Packages that are too large or oddly shaped often require special handling, extra storage space, and non-standard delivery routes. On the other hand, right-sized packaging streamlines fulfillment, transport, and sorting across logistics hubs.

Right-sizing also reduces the need for excess filler, lowers dimensional weight charges, and makes loading and unloading more efficient for carriers.

2. Pre-Assembled or Easy-to-Pack Designs Save Time

Every second counts in a busy fulfillment center. Packages that are quick to fold, seal, or label significantly reduce packing time per unit. This time saved scales up fast, especially for high-volume operations.

Examples include:

- Auto-lock bottom boxes

- Mailer boxes with peel-and-seal strips

- Pre-printed shipping labels integrated into the box

3. Better Packaging Lowers Shipping Errors

Poor packaging increases the chance of damage, lost items, and delays due to reprocessing returns or complaints. Efficient packaging means:

- Securing the product properly

- Label placement that’s scannable and visible

- Compliance with carrier size/weight standards

Fewer errors mean fewer re-ships and better on-time delivery rates.

4. Lightweight Packaging Increases Speed and Reduces Costs

Lightweight packaging options—such as corrugated mailers, padded paper envelopes, or eco-friendly pouches—cost less to ship and are easier to handle during sorting and delivery.

Plus, lighter packages reduce load weight in delivery trucks, which may qualify for faster routing and fewer shipping restrictions.

5. Stackability Improves Warehouse and Transit Flow

Packaging that stacks neatly without crushing or slipping improves the efficiency of warehouse operations and transit logistics. Stackable designs allow faster loading and reduce the risk of damage in transit.

Consider packaging with reinforced corners or flat tops designed to hold weight evenly.

Final Thoughts

Packaging isn’t just about protection or aesthetics—it’s a key player in logistics. By optimizing your packaging for efficiency, you’ll cut packing time, reduce errors, lower shipping costs, and most importantly, deliver faster.

At Best Box Store, we help businesses choose packaging that supports both speed and sustainability. Let us help you reduce delays and delight your customers with packaging designed for performance.

Looking to speed up shipping? Contact us for high-performance packaging →